Operational Excellence

A Marketing Story - What Color is that Carton?

Hi folks, I’m Walter Wardrop, an Operations Management Coach at the Growth Roundtable.

Hi folks, I’m Walter Wardrop, an Operations Management Coach at the Growth Roundtable.

Years ago, while doing new product development, I had the opportunity to visit a paper converting company. They were about to make a run of new seafood cartons with modified graphics. I had not been to a large packaging plant before and was quite impressed by the six and eight color high-speed offset presses they used. These machines were large enough that they could run a sheet of our cartons with 6 to 10 flattened cartons printed on each sheet. I was present at the start of the run, and I was watching the operator adjusting the colors in relationship to what was coming out the end of the press. As those of you that have done this before know, it is very difficult thing to do this when running one at a time, rather than 75 per minute when operating the press at full speed. The thing I found most fascinating was the people from my company standing around looking at the sheet of product and asking the machine operator to bring up the yellow better, while taking down the blue or other such things as this. The poor operator would try to adjust on colors on something that was running at one hundredth of the speed he would normally run it. While looking at this, I asked the packaging sales rep standing with me whether this was a normal method for proofing the start of a run. The man gave me a sardonic smile and took me to the quality control room just to the side of the working press.

Inside this quality room there was an assortment of machinery and sitting on the bench was the file folder with the carton samples in question. The file contained three samples of the graphics. We specified what was too light in color, what was too dark, and what we wanted to see sitting between these two samples. I pointed to a machine on another bench and asked if that was a machine capable of reading the colors on the carton. Again, the company sales rep sighed and said that was exactly the purpose of the machine. I then looked out at my colleagues working on the floor, who were making no attempt to bring the samples into the office and test on the machine. We both smiled and shook our heads and wondered at people that have the needed technology at their disposal, to give the correct answer, but still want to guess at solving the problem. The packaging company owned the machinery, and from the readings would have known what colour to increase or reduce, but nobody was using the technology. In this case the problem was us, the customer. The company was being too polite to insist that we use the appropriate machine.

How often have you been in the position where you need a piece of technology that is not present, and you must estimate? It is just as bad when you estimate, and the technology is there but not being used.

A Marketing Story - VisiCalc got me to Saudi Arabia

Hi folks, I’m Walter Wardrop, an Operations Management Coach at the Growth Roundtable.

Hi folks, I’m Walter Wardrop, an Operations Management Coach at the Growth Roundtable.

Back around 1988, while working for a large seafood company, I had the occasion to start working with an early generation spreadsheet tool called VisiCalc. As part of the work-study group, I was often called upon to give some estimate of the human productivity costs associated with new seafood products being created. This would often turn into a request to also gather up some of the additional costs that might be associated with a new product costing.

I saw the opportunity with this spreadsheet program to actually generate a one-page document that I could show to the marketing department, with a fairly accurate answer. When we met, we could also use the spreadsheet to adjust various parameters, in order to meet the cost price that we needed for the client. You have to remember that most retail products have a pre-determined selling price, and the manufacturer works back from that point to determine what price the product has to have leaving the factory.

Different products have different costing multiples. A garment might have a multiple of four, where something the apparel manufacturer makes for $10 FOB factory, is $40 on the retail rack. Food does not need such a large multiplier, but I still remember the seafood industry having a multiplier of about 2.5. A pound of a certain product that was a dollar at the seafood plant, was showing up on the grocery store shelf for $2.50.

But back to the VisiCalc. To build a working spreadsheet, I first went down to visit a friend in accounting where I obtained a master spreadsheet of all our seafood products. This master list had over 400 lines, as the company had that many different products. Then we got to the number of columns, which my fading memory remembers as 150 due to different species, packaging, and some labor calculations.

Using this master, I built two or three spreadsheets for retail products in the wet fish area, and others for food-service products in the same plant. Then there was half a dozen for some of the products in the cooked fish area. As a request would come in from marketing, I would determine what seafood variable costs I would add to the hard costs such as packaging and overheads Then an estimate of the likely labor requirements and costs that would be associated with this new product. Press the button and presto, an estimate of what the new product would cost in the factory.

These numbers were something of a guess, mixed with an estimate, and rounded out with numbers plucked from thin air. But the key was that the numbers I was coming up with were related to actual numbers on the production floor. I usually estimated the new process would be slightly slower than a similar process. This would allow me to build a quick answer for the marketing department. Marketing had been used to waiting months if they got an answer at all.

Word of this project, and the quick results coming from it, quickly spread through the company. I was happily surprised when one of the VPs dropped by to see me and asked to borrow some of my time over the next few days. He had a delegation visiting from Saudi Arabia and wanted my help in building some spreadsheet models to help the Saudis decide on their product mix. They wanted to form a partnership with our company and needed our help in designing a cooked fish processing plant for Saudi Arabia.

We took over a boardroom and turned it into what modern business guys are calling a war room. We did not have the term back then, which was probably just as well as there was a slight conflict taking place between Iraq and Iran at that point in time. With my spreadsheets working on what we jokingly called a portable computer, we were able to create six primary seafood products. We had some idea of what they might cost, and what kind of production lines we would need in this new plant.

The beauty of this is that we were producing some reasonable documents, with a solid set of numbers on them, and what estimates we used were agreed-upon as a group.

So how did I get to Saudi Arabia?

Several months after this meeting, I was called in to see the same vice president that I had worked up the Saudi numbers with. The skirmish between Iraq and Iran was still going on. The Saudis had requested that we send a small delegation over to visit their wet fish plant (to which the cooked fish plant would be attached). The VP had asked several engineers if they could go to Saudi Arabia, to look at the proposed site for the cooked fish processing plant. These engineers had families and had politely declined due to the rather active war being waged in the area. The VP then approached me, as I was a bachelor at the time. I jumped at the chance. I will happily point out that it was my use of a simple spreadsheet program called VisiCalc that gave me this trip to Saudi Arabia.

The trip was an excellent one, and generated stories of its own.

A Marketing Story - The Blue Wall

Hi folks, I’m Walter Wardrop, an Operations Management Coach at the Growth Roundtable.

Hi folks, I’m Walter Wardrop, an Operations Management Coach at the Growth Roundtable.

In many consumer-oriented industries, as we start a new product, we do focus groups and surveys. You may have seen these individuals, standing around a certain area of the store, with a clipboard in hand looking anxiously for somebody to slow down. They want to ask consumers a few questions and get their opinion on a product or food. In our case, the surveyors were asking people if they liked our Cod product. One passing individual said they always liked our products, and they bought the blue box every time they were in the store getting seafood. The surveyor wrote this comment down verbatim. When the survey got back to the marketing department, they quickly realized that this was a very interesting comment. The reason it was so interesting, was that this particular cod product did not come in a blue box.

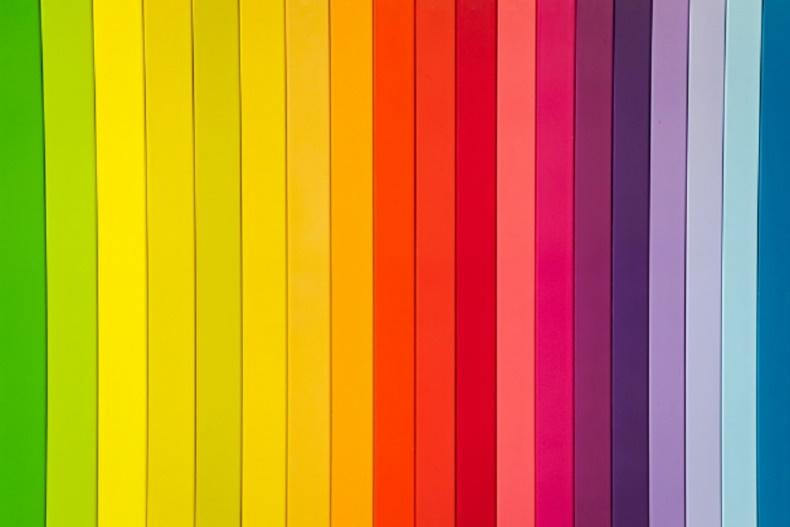

The marketing group then went down to a local grocery store, to have a look at the frozen seafood section of the cabinets. What they quickly came to realize was that they were looking at a rainbow of colors scattered through the cabinets. It would be hard for a customer to determine brand based on colour alone. At this point the company set about changing the colours of our cartons, making sure that every box and a blue border around the edge. In the center we would have graphics and maybe a secondary color to reflect the species of fish. What we had created was what the marketing people called “A blue wall”.

I was never sure just how well this worked, but I do remember looking at the seafood counters from that point on and seeing that our product was recognizable as a blue section among a rainbow of different cartons. Always listen to your customer, as they are the only one with a wallet.

A Marketing Story - Just Who is the Customer

Hi folks, I’m Walter Wardrop, an Operations Management Coach at the Growth Roundtable.

Back in the early 1980s, I was working for Michelin tires. Michelin was making a well-respected tire that lasted for nearly 100,000 kilometers on cars. Due to the quality, and durability, Michelin was able to charge a high price point for these tires. The result was that the tires were basically being sold only to OEM customers such as Ford. Every spring and fall the sales staff would go off to Detroit and be told by the car companies what the OEMs were buying for the season, and what they would pay. You will notice that Michelin was not telling Ford the price, but rather Ford was telling Michelin.

Due to the durability of these tires, Michelin was not able to sell a lot of replacement tires. This was not good for Michelin, as it restricted the market to just being OEM customers, who as already mentioned were likely to dictate the price, more than ask the selling price. Michelin, therefore, had to come up with a new direction. Their new direction was to start a new marketing campaign, which most of you will remember as the babysitting in the center of the tire.

What was the basis of this campaign? The people in marketing recognized that they had been trying to sell the tires to the male of the family. It was time to start trying to sell the tires to the female of the family. What happened with the campaign was that the mother watching the television would see this ad with the baby in the Michelin tire, and the implication of safety for the vehicle in which the mother was carrying the baby. The mother would then turn to the father, and request of her husband that he buy Michelin tires for the family station wagon or minivan that she was the driver of.

The husband would then start into a long justification for staying with the no-name brand of replacement tires that he knowingly bought because of how far they were through the lifecycle of the vehicle they were driving. He would point out that the Michelin's were a little more expensive, and they would last far longer than what life was left in the vehicle she was currently driving. They would just be giving good tires away to whoever bought the used vehicle from them.

At this point you need to visualize the mother turning and saying “Oh, I am sorry dear, was there an inflection in my voice. I apologize if you thought I was asking a question”. The husband, with a much higher pitch to his voice, would reply “Yes dear, I will have Michelins on the minivan shortly”.

Michelin marketing had figured out the correct order point to sell replacement tires. They had been too busy looking at the customer, Dad coming to the tire dealership, and had missed until that point who the consumer was, Mom with the minivan. I am not sure what the actual number of sales became for that campaign, but I can still mention the baby in the tire to people 30 years later, and they can remember that visual. Often they get a chuckle from the thought of the wife leaning over and saying “I apologize if you thought that was a question”.